Mimaki JV 100-160 Roll to Roll Inkjet Printer - IN STOCK

With two newly developed heads, the JV100-160 has pursued high quality, high productivity, and stable operation as a eco-solvent inkjet printer.

In addition to NCU (Nozzle Check Unit), NRS (Nozzle Recovery System), and MAPS4 (Mimaki Advanced Pass System4) that enable stable and high-quality printing, DAS (Dot Adjustment System) is also provided to new "100 series" printers. Dot position correction and feed amount correction, which used to be manual operations and require time and effort, can be automated, reducing the workload on the operator.

DAS (Dot Adjustment System) NEW!

The JV100-160 is equipped with the DAS, a function to automatically adjust the dot position and feeding amount that affect print quality.

When media or printing conditions are changed, an adjustment of ink dot position and media feed amount to suit is necessary.

As the DAS automatically performs these operations, printing can be performed without any labor or variations in adjustments by the operator.

Mimaki technology that enables stable and high-quality print

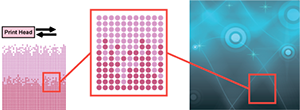

MAPS4

Generally, swath boundaries are straight lines. Therefore, a slight misalignment between boundaries causes banding or uneven color printing. MAPS4 (Mimaki Advanced Pass System 4) reduces banding and uneven color printing with blurred boundaries similar to gradation printing.

MAPS ON

Banding and uneven color printing are reduced by scattering swath boundaries. Beautiful print image is obtained.

MAPS OFF

Bandings appear on swath boundaries. Print quality is remarkably degraded because banding is recognizable on each boundary.

| JV100-160 | |||

|---|---|---|---|

| Cartridge type | Bottle type | ||

| Print head | On-demand piezo head (2 staggered layout) | ||

| Print resolution | 360 dpi, 600 dpi, 720 dpi, 900 dpi, 1200 dpi | ||

| Ink | Type/ Color | Eco-solvent ink ・AS5 (C,M,Y,K,Lc,Lm,Lk, and Or) ・SS21 (C,M,Y,K,Lc,Lm,Lk, and Or) ・BS4 (C,M,Y, and K) *Only available in specific countries |

Eco-solvent ink ・CS250 (C,M,Y, and K) *Only available in specific countries |

| Capacity | 600ml Ink pack *1 / 2L Ink pack *2 | 1L bottle | |

| Maximum print width | 1,610 mm (63.4 in) | ||

| Media | Maximum width | 1,620 mm (63.8 in) | |

| Thickness | 1 mm or lower | ||

| Roll diameter | φ250 mm or less | ||

| Roll weight | 45 kg or less | ||

| Roll inside diameter | 2 inch / 3 inch | ||

| Certifications | VCCI class A, FCC class A, CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, ENERGY STAR®, RCM, EAC |

||

| Interface | USB2.0 / Ethernet 1000BASE-T | ||

| Power supply | Single-phase (AC100-120 / 200-240V±10%, 50/60Hz±1Hz) x2 | ||

| Operational environment | Temperature: 20–30 °C (68–86 °F) Humidity: 35–65% Rh (Non condensing) |

||

| Dimensions (W×D×H) | 2,775 x 700 x 1,392 mm (109.3 x 27.6 x 54.8 in) | 2,775 x 700 x 1,475 mm (109.3 x 27.6 x 58.1 in) | |

| Weight | 166 kg (366 lb) | 168 kg (370.4 lb) | |

*1 600 ml ink pack requires eco cartridge (OPT-J0361). Eco cartridges can be used repeatedly by replacing ink packs.

*2 Optional Mimaki bulk ink system 3 (MBIS3) is required for using 2L Ink pack.